PRINCIPLAY®

LEARNING BY DOING

Extraordinary Results Through Attention to Work and People

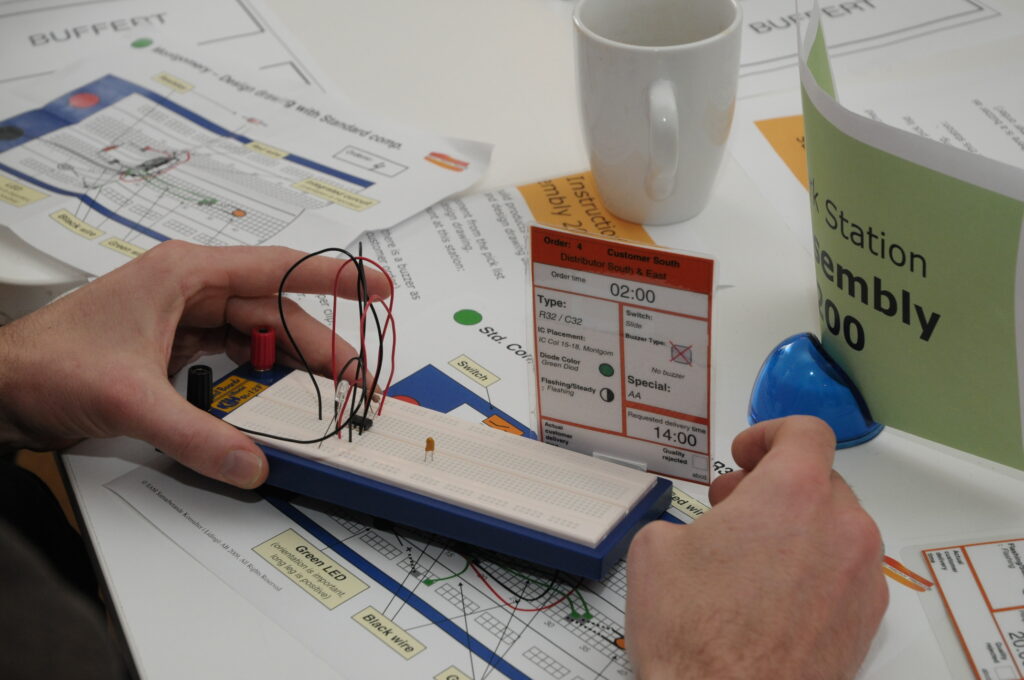

What is special about a Principlay ™ workshop is the simulation of a real work environment with real work functions, roles and processes. The simulation emphasizes the power of learning by doing. The basis of the game is to use principles as the start for improvement discussions, hence the name Principlay™. Problems similar to everyday situations arise in the simulation and can be solved in a structured way using SAM’s mindset model, the principles and its methods.

Interested? Contact our colleague Erik for more information

Principlay ™ - The Workshop

A Principlay® workshop may span from half a day up to a week but during a typical one day session we simulate and reflect, test solutions and discuss how to go forward in a realistic simulation with real product variants in real material and information flows.

Principlay ™ - The Origin

Principlay® was originally developed by SAM to train people in both general flow oriented principles and practices. and over the years we have developed more than 30 customized simulations, tailored to address very specific issues or situations that our clients have faced. Currently over 15,000 participants from all over the world have participated. We have simulated all types of work in all kinds of businesses: From sales to product development, from production to purchasing and much more.

A few examples of Principlay that SAM can provide and customize:

Principlay Classic

Shows how application of the principles Need-Driven Flow, Right from Me, Visualization, Clear Normal Mode and Constant Improvement develops in a production flow from Order to Customer. Relationships between stress, pace, quality problems, unclear work standards, customer satisfaction and waste become clear. With the use of electronics, quality problems and challenges arise spontaneously without being introduced. This allows for actual root-cause analysis to be performed. the need to be introduced. Can also be expanded to highlight the different effects of a supportive leadership vs an authoritarian leadership.

Principlay Order To Delivery

Here, simulation of the interaction between two production sites and order management (including retailers, wholesalers and production planning), and the difficulties to keep the customers satisfied with the right product at the right delivery time. Participants test and show the importance of pushing the planning point, planning visually and letting order information accompany the product. Effects will be reduced administration and waste in several stages, higher delivery precision, more efficient collaboration, shorter lead times and faster reactions to customer changes.

Principlay Simprovements - effective deviation meetings and improvement meetings

Simulation of both a deviation management meeting and improvement meeting to illustrate the dynamics of visual control in a collaborative environment that triggers commitment to quickly create their own Pulse meetings. Can be done in five different environments in a fun way based on improvisation. It is preferably followed by a discussion on how to set up real meetings in the day-to-day work environment. Can be combined with a presentation how to build and implement a deviation management system in different kind of flows.

Principlay Modular Production

Customers of today demand more and more variety and complexity from products and services. At the same time, customer requirements, pace of innovation and efficiency are increasing. The combination of Management by Means and modularization is a key to high levels of customization, with short lead times, high quality and low costs – throughout the life cycle, from product development, manufacturing, service and recycling.

The Modular Production simulation includes the central roles in the industrial and commercial system – Production, Logistics, Purchasing, Planning, Marketing, Customer, etc. The simulation provides a unique first acquaintance with the main principles of modularization and the and its effects on the value chain. The participants will experience the advantages of a modularized product in transforming the production flow beyond what is possible with only a conventional ‘lean’ approach.

The simulation is carried out in several rounds where participants step by step improve the whole ‘company’. In addition to the simulation rounds there are presentations, cases, discussions and workshops. In the design workshop, all participants take on the role of Product Developer. Based on a customer needs analysis, one can practice the modularization principles and SAM’s method for modularizing and developing the company’s customer offering.

After the design workshop the participants get to experience and can see the effect of a modular product program through its role in the simulation. The training is available in three different versions 2 days, 1 day or half day.

Principlay Infrastructure & Installation development

Customers of today demand more and more variety and complexity from products and services. At the same time, customer requirements, pace of innovation and efficiency are increasing. The combination of Management by Means and modularization is a key to high levels of customization, with short lead times, high quality and low costs – throughout the life cycle, from product development, manufacturing, service and recycling.

The Modular Production simulation includes the central roles in the industrial and commercial system – Production, Logistics, Purchasing, Planning, Marketing, Customer, etc. The simulation provides a unique first acquaintance with the main principles of modularization and the and its effects on the value chain. The participants will experience the advantages of a modularized product in transforming the production flow beyond what is possible with only a conventional ‘lean’ approach.

The simulation is carried out in several rounds where participants step by step improve the whole ‘company’. In addition to the simulation rounds there are presentations, cases, discussions and workshops. In the design workshop, all participants take on the role of Product Developer. Based on a customer needs analysis, one can practice the modularization principles and SAM’s method for modularizing and developing the company’s customer offering.

After the design workshop the participants get to experience and can see the effect of a modular product program through its role in the simulation. The training is available in three different versions 2 days, 1 day or half day.

Principlay Process Industry

Accelerating improvements in process operations and develop systematical problem-solving capability suited for the process industry environment.

Principlay® Process is specifically designed to cover process industry characteristics such as: Machine intensive processes and high CapEx, diverging flows, maintaining high and even quality over time, difficulty in finding root causes of deviations, and strong interdependence of process parts

Participants will experience application of lean principles in process industry-like environment, gain understanding of how to apply lean principles in their own work, get improved ability to handle deviations, and be inspired to continue developing their improvement methodology and mindset.