Digitalization

A Human Affair

The digital world is growing exponentially. Integration of intelligent systems in all lines of production and services is rapidly increasing. Today the ability to gather and process data, receiving and sending information have initiated the possibility to have more accurate date in real time, compared to past times. Connecting a vast amount of systems and having them interact allows growth from new perspectives and gives new opportunities

For any organization, independent of business, the present digitalization boom is important to embrace, to sustain the competitive edge of an organization. Of course, the digitalization era started 70 years ago with Colossus or maybe with the launch of IBM-32 in the late sixties? None the less, the world has reached a point of development in digital tools that has made it necessary for also more traditional processes and organizations to adapt to the new times.

For manufacturing or services processes digitalization has and will have profound effect on development moving toward more automated and autonomous processes.

Starting already in the second half of the 18’s century with the first industrial revolution, automation has become a profoundly integrated part of modern production. Developed from steam engine aided looms and mining pumps intelligent systems has led us moving toward almost autonomous production lines with limited need of human interaction. The German initiative “Industrie 4.0” is probably leading the way when it comes to such production.

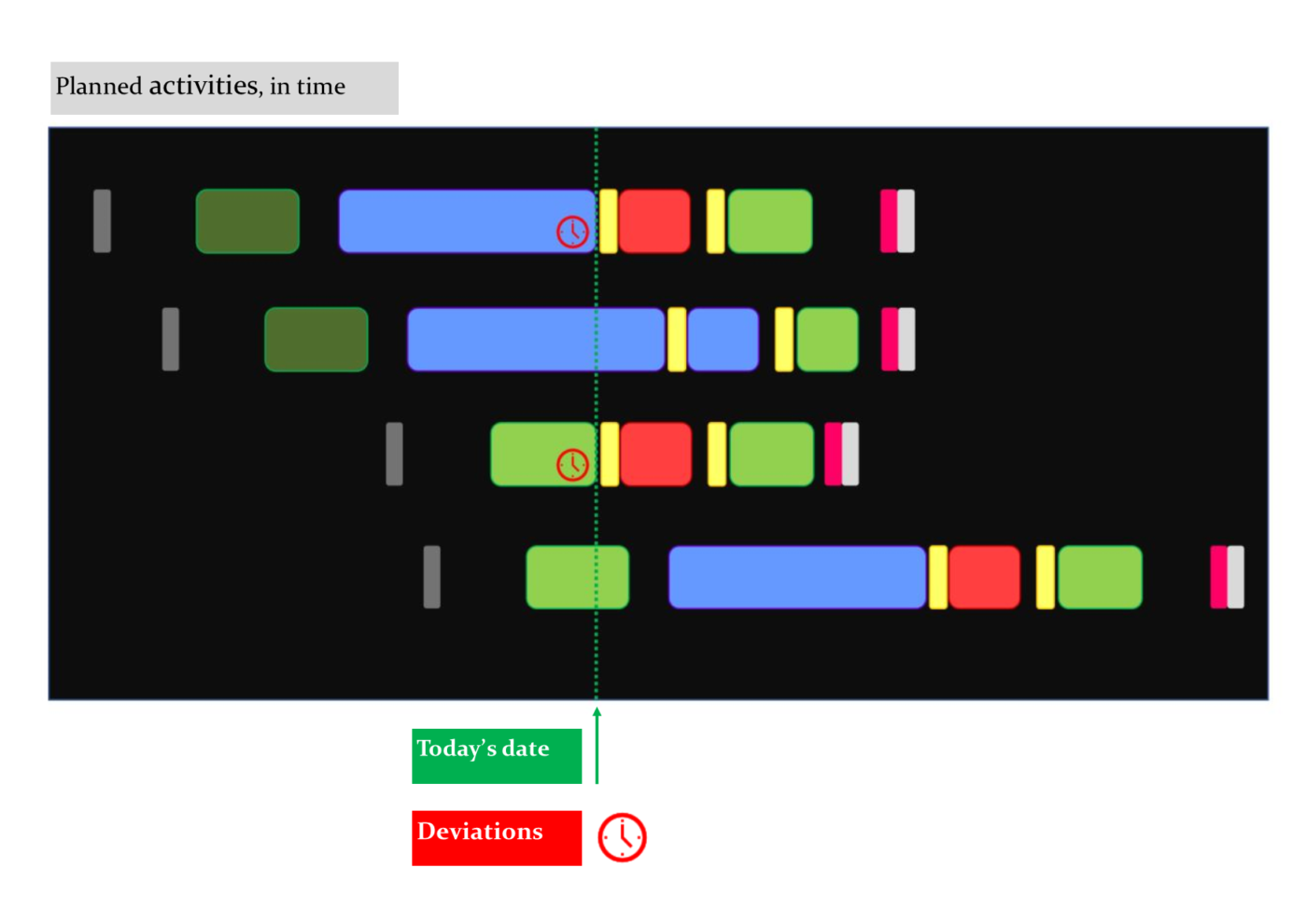

However, all facilities and business have people interacting at some point of the complete process. There are very few completely automated processes in operation, if any, that also manages to auto correct deviations, mistakes, scrap or similar. There is always need for human interaction for management and operation of even the most automated processes. So, how do we fit in people in the processes to come? The risk is that we become seduced by the beauty of technology and forget that the systems need more that metal, zeros and ones

A usable key-word might be autonomation. The word itself is more or less invented by Sakichi Toyoda, inventor of the auto-activated weaving machine and founding father of the Toyota motor corporation. The word autonomation is commonly translated “automation with a human touch”. Everything and anything require a cooperation between people and machines. Importantly the cooperation should generate positive synergies. The risk is, however, that the cooperation is unsynchronized. The machines might be developed inconsiderate of the people having to interact with them or people are not sufficiently trained in how to interact with the machines. The automation is supposed to increase productivity and improve the work environment for the humans. How do we ensure the implementation becomes the most beneficial for the organization long-term?

The fast technological development is beneficial, but it is easy to become blindly captivated by it. The risk is becoming boxed in an un-flexible system ending up in the hands of the technology instead of using it for our own benefit. The systems supposedly aiding the processes are not supporting the organization, but becoming counterproductive.

The conclusion is that no matter how fast the development is there is a balance to optimize the output and long term profitability, as well as the work conditions for people. The most important is that the customer is satisfied. Hence, to sustain income as well as reducing cost and therefore the company profits. Autonomation is a key factor to obtain that, optimizing the interface between humans and machine and allow feedback of more useful information to users, human or transistor-driven.