The predicament of automotive electrification – securing profits for next generation vehicles

Category: Modularization

”Extraordinary results through attention to work and people.”

Electrification of vehicles is what is on everybody’s mind right now. It is considered environmentally friendly and provides a lot of benefits. In time, there is a high probability it will be the preferred drivetrain in vehicles. The old automotive industry has been seduced and frightened by the challenger Tesla, and the breakthroughs they have done. Both technically and in the way they have put electrification in the minds of customers and decision makers.

Forgotten is the complex minds and ways of customers, markets and politicians, as well as the inertia of infrastructural development. Customers seldom know what they want, politicians change their minds and geographical markets are different. In addition, to build a robust charging infrastructure will take time.

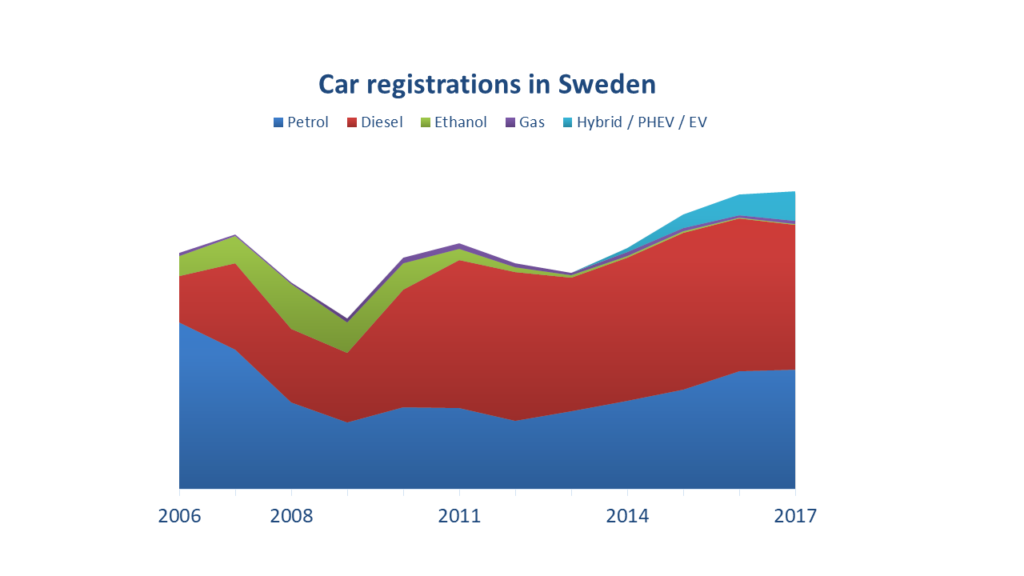

The Swedish market provides an example. In the beginning of the millennia, Ethanol was the savior. Politicians pushed for ethanol, and with government subsidiaries, the sales took off. While the technology was not hard or expensive to implement by the manufacturers, they needed to adapt. Suddenly the market changed. Ethanol was not seen as environmentally friendly, there was issues with the technology, and at the same time, the subsidiaries was removed. Nowadays no one is talking about ethanol, at least not for consumer vehicles.

It is a dead market. The case for electrification is different, but, at the same time, the lesson must be learned. One can be sure that the future markets, customers, and governments will have different needs when it comes to electrification.

So, even though the long term development towards vehicle electrification seems clear, in the mid-term, the uncertainties builds up. Remember that hydrogen/fuel-cells is still an option. This is why it is liberating to read about BMW and how they are mitigating these uncertainties in their new CLAR platform.

“BMW is hedging in bets in being able to respond to every type of drivetrain a customer might desire as it “simply cannot be sure” how much demand there will be for any particular drivetrain in the future, according to Lutz Meyer, who works on BMW’s product strategy for architectures. “

BMW accept the fact that there are certainties (people will want personal transportation…), and that there are uncertainties (..but we don’t know which drivetrain the customers will go for). But how do they handle the uncertainty? They could have decided to go with 2 platforms – one electric and one combustion platform – or do according to the quote: One platform independent of the drivetrain.

In the case of 2 platforms, which volumes should they plan for? And how do you choose which customer segment you will target with which platform? It is hard to plan and invest in the industrial system (development, production, logistics, sourcing, etc..), when you have large uncertainties in volumes. Suddenly the demand for electric platform cars takes off, and at the same time the demand for your combustion platform cars plummets. No demand for one industrial system, and the capacity for the other industrial system is not enough. Imagine the costs and the lost potential revenue!

In the case of one platform, you design the platform according to the volumes you need, and handle the uncertainties in drivetrains on a lower level. When the demand in drivetrains shift, you are faced with a confined problem. How to manage the volume changes for drivetrains instead of volume changes for whole cars. There will be costs adapting to the changing volumes, but at a manageable level, with a shorter lead time.

BMW’s thinking resembles true modularization, and in this case it is used to hedge for uncertainties in future drivetrain demands.

But the modular thinking is not only applicable to the automotive industry, but to all products and services. It is not only a tool for mitigating volume uncertainties, but a platform for innovation. The key here is customer need. True modularization always begins and ends with the customer need. The ability to develop and build a product which can provide for not only the current needs of the customer, but also, with short lead time, develop and produce according to customers’ demand. All of this within the same industrial system. This is the endgame!

This is also what can make you more profitable. Our experience from customers tells us this. The standard high volume products has low margins and provides economies of scale, while the low volume customer unique products provides the profitability.

So how do you start? In small steps of course, and with a clear path ahead. The path to a modular product, or rather company, contrary to what one might believe, is not a purely technical one. Sure you need to have savvy developers, with deep technical knowledge, but the key is the mindset and culture of the company. The modularization principles must be learned, used and practiced by everyone in the company, from the sales reps to the factory workers. It is a daunting task, but a profitable one.