Cultural Transformation

Case: Transforming an old-fashioned production strategy

The Client:

Heavy equipment manufacturer

A family owned American manufacturer of equipment for installation of cables and pipes. The company was founded in the 1940s and still has the main facility in a small rural town in the American mid-west. It had about 1300 employees and a turnover of about $400 million US.

The Challenge:

Production strategy transformation

The company’s implementation of Lean had stalled and, similarly to many other companies, the existing implementation was limited to manufacturing. Consequentially, the company was suffering from late deliveries and a large parts population. Additionally, both the final product and the production strategy to make it was old-fashioned. If the company didn’t change their manufacturing process, they were at risk of losing their competitive edge.

After engaging SAM to address issues in product development and to improve the flow of new products to manufacturing and the market, the company recognized SAM’s emphasis in a common mind-set and SAM’s implementation methodology. They realized that what the company needed was to make a more fundamental cultural change to address not just the symptoms but also the underlying core of their issues.

The Success:

Lean and efficient flow

- Wide-spread cultural shift, moving from “We against the rest of the organization” to “We as a one team”. There was understanding and appreciation for the common challenge and for the common goals.

- Dismantled administration barriers between the different departments and organizational segments of the company.

- Better improvement culture on all levels in the company, with understanding for what factors drive and sustain improvements in a company.

- Changed and improved behavior among leaders and employees, everyone giving support to the organization and each other.

- Better communication throughout the organization

How we did it

Change begins and ends at the top of an organization. With this in mind, SAM worked closely with the company’s management team and was deeply involved in every step of the change process. SAM was present and available right in the middle of the everyday operation, giving support and coaching to individuals on all levels of the company.

Together with management, SAM discussed and reflected on the company’s culture, its history and its heritage. Looking back, the company was a true success story that was powered by a healthy mind-set and work routine. However, as time passed these had not been adjusted to reflect the changes in the market, making them out-dated and rigid. The challenge became to understand the essence of the company’s past; what was the core that made it successful? The discoveries from this soul-searching was then combined with a vision for long-term success, specifying what requirements needed to be fulfilled to get there.

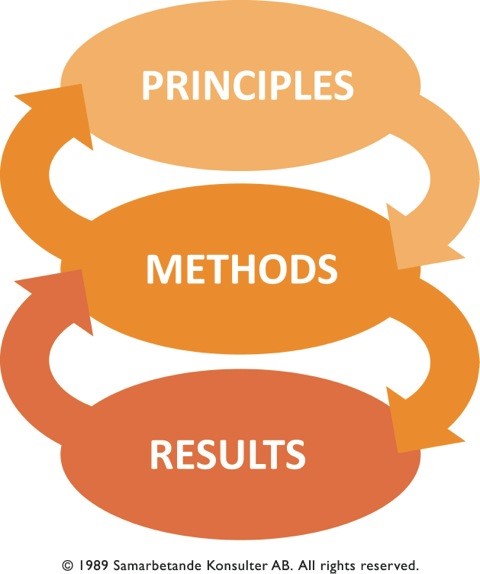

With a goal in sight and an idea of how to get there, extensive discussions worked to crystallize a set of company principles that could give common view, mind-set and strategy for the company. These could be shared, promoted and used to improve work methods, becoming the foundation for the development of the company. The principals affect the entire company, from manufacturing, sales and product development to support functions such as finance and human resources.

Mandatory training was carried out for all managers and leaders. The purpose was to use reflection and discussions to further solidify the principals in the organization. An important aspect here is that the discussions concerning the principles were in close connection to the real operation. Within the cross-functional discussion groups, an atmosphere of affinity and holistic understanding was nurtured, striving to give new insights to the issues and challenges that other departments faced. Simply having a forum that welcomes discussions can result in several improvements – as was the case here.