Digital Planning Board

Case: Real-time visualization for on- and off-site personnel

The Client:

Global Truck Manufacturer

A Swedish haulage truck distributor that was founded in the late 19th century in a small, rural town. By the early 21st century, the company had grown into a multi-billion dollar company with employees and customers all over the world.

The Challenge:

Cross-Functional Information Sharing

At the company, a manual and physical planning board was used to visualize their customer orders and production; Personnel meetings with visual information is an unbeatable tool in establishing trust and mutual understanding of what is actually happening in a production flow.

However, the staff at the company was struggling with the implementation and retinue of said planning boards. There were several issues that the physical boards couldn’t handle, primarily that not all team members had the possibility to physically participate in the meetings. Sales staff for example could almost never attend due to the nature of their work. The resulting situation was that the meetings lost importance and the communication between departments broke down. It became increasingly difficult to ensure the product delivery to their customers, and both quality and lead-times suffered because of it.

The Success:

Real-Time Digital Planing Board

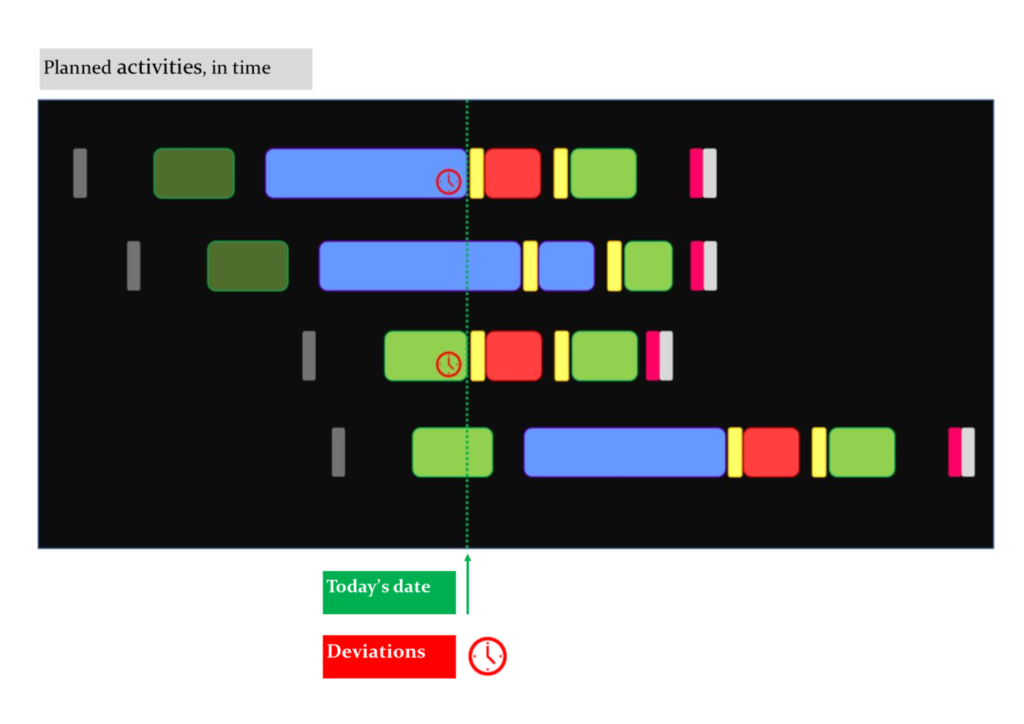

- A digital planning board:

- based on existing processes and needs,

- allowing everyone – independent of geographical presence – to be involved,

- sustaining the direct, tactile planning approach,

- and connected to the IT infrastructure to minimize administration.

- Improved presence and involvement in the planning necessary for increased productivity with sustained precision and efficiency.

How we did it

Two of SAM’s principles are to Understand the Customer Viewpoint and to have a Holistic Understanding of Details. With these in mind, SAM’s first step was to understand what the original planning boards were meant to accomplish.

When using the planning boards, the company’s idea was to gather people from all vital departments – planning, production, inventory, sales, support and so on – and establish a common view of the current status. The meetings were meant to help prioritize tasks and issues, based on the combined knowledge of customer needs and internal capacity; What orders had to be rushed? Had a customer changed their mind? Was a part missing that was needed to complete a delivery?

However, with parts of staff geographically dispersed and low attendance much time was spent on simply keeping the systems and boards updated. The planning boards were deemed vital for successfully completing orders on time and with the right quality. It was however clear that the retinue around them needed to change. Thus the question became how to simplify for all needed personnel to attend the meetings without losing the common view and the positive effects of visualization.

One idea that was brought forward was to digitalize the board to enable participation from somewhere else. However, by simply moving to a computer, the visualization methodology and the direct, tactile approach to moving orders and seeing changes in real-time would be lost.

To solve this issue, SAM worked closely with the team members to developing a more tactile and visual version of the digital planning board. The success of this digital visualization board was enabled by SAM continuously working with the teams on site, tirelessly evolving and adapting both the planning board and how it could be utilized.

The final tool that was created was based on well-known, established and widespread methods. Hence, digital planning and visualization board was embraced by all participants from the start.